1. What tension should be applied to the blades?

The blade can withstand a tensile stress of 8 tons at the first cut and 7,5 tons at the last cut, if the minimun working height is not exceeded.

2. What is the minimum working height of the blade?

The blade withstands a maximum shearing stress up to a section of approx. 125 mm2, which is equivalent to height x thickness 25 x 5 mm or 30 x 4.2 mm. In certain cases it is possible to exploit the blade up to 25 mm2 with minimum height 5 mm, but to the detriment of production and with considerable risks of breakage and poor sawing.

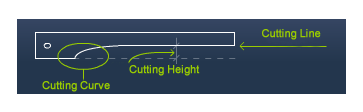

3. When must the cutting curve be removed?

The cutting curve sometimes produces a step on the slab that starts from one side and runs towards the centre with variable length and depth and with loss of usable surface. This phenomenon is eliminated by removing the cutting curve when it has a height of 17-25 mm with respect to the cutting line; this measurement will vary according to the frame used.

4. From the technical point of view what is the optimal blade dimension?

The dimensions that provide the best compromise between cutting efficiency and speed are: height 90-110 mm and thickness 4.5 mm.

5. What grit dimensions should be used?

The best results are obtained by using:

→ Coarse grit with blade thicknesses 4.5-5.2 mm

→ Medium grit with blade thicknesses 4.2-4.7 mm

→ Fine grit with blade thicknesses 3.8-4.3 mm

6. Which blade offers maximum cutting efficiency in terms of m2 of slabs cut per m3 of block?

The blade with height 80-100 mm and thickness 3.8-4 mm.

7. What is the optimal dimension of the fixing nail?

The best results are obtained with a 20 mm hole and 18-19 mm nail.

8. What is the best blade assembly system?

There are two optimal systems and they differ only as regards the starting point: in the older system the first blade is placed on one side of the block and is more suitable when fitting blades for 20 mm thick slabs, blades with maximum thickness 4.5 mm and tensioner pitch 27 mm; the second more recent system places the first blade at the centre of the block and is used more frequently with tensioner pitch 27 mm and blades with thickness > 4.5 mm as it permits optimal closing of the pack even without the starting spacers.